Bayani

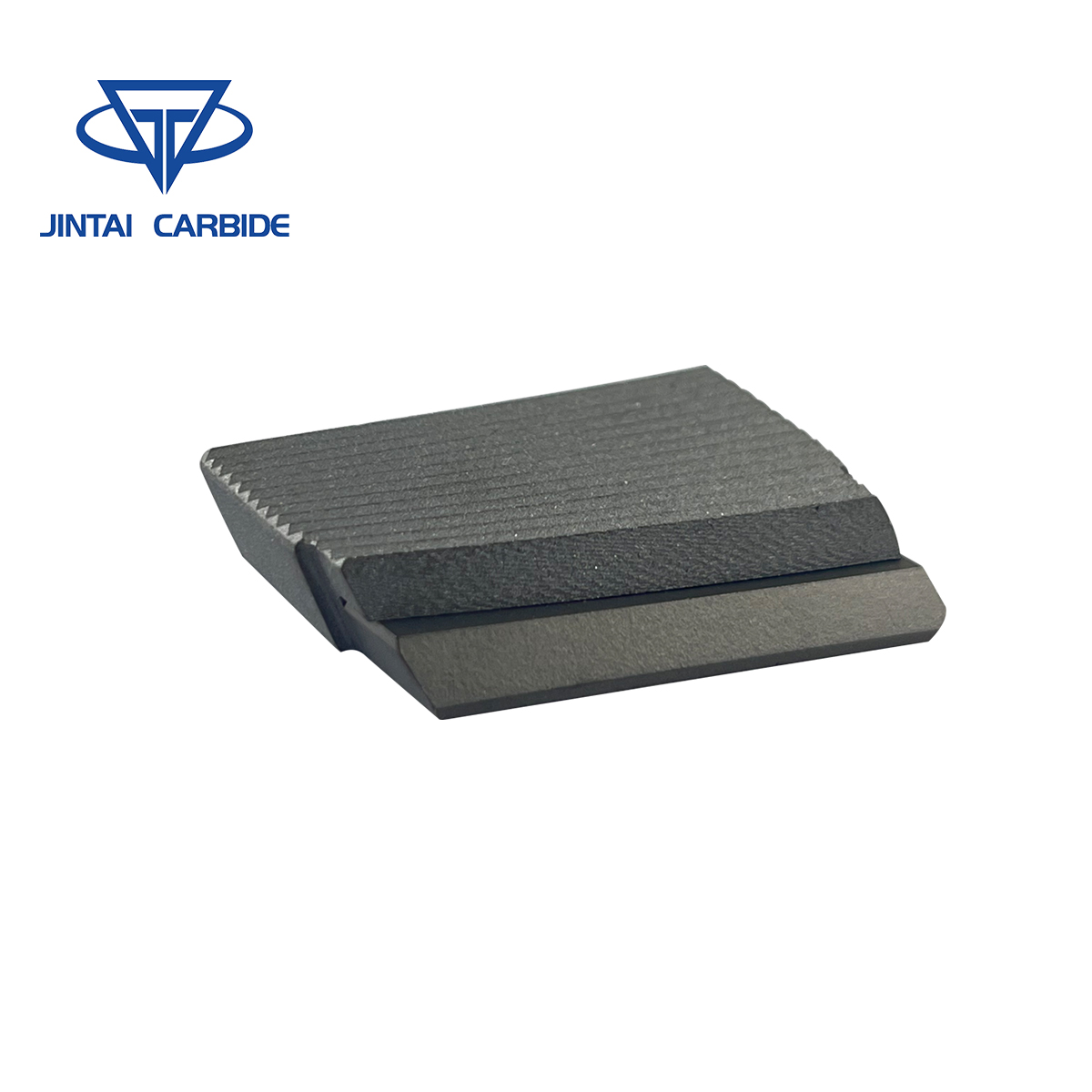

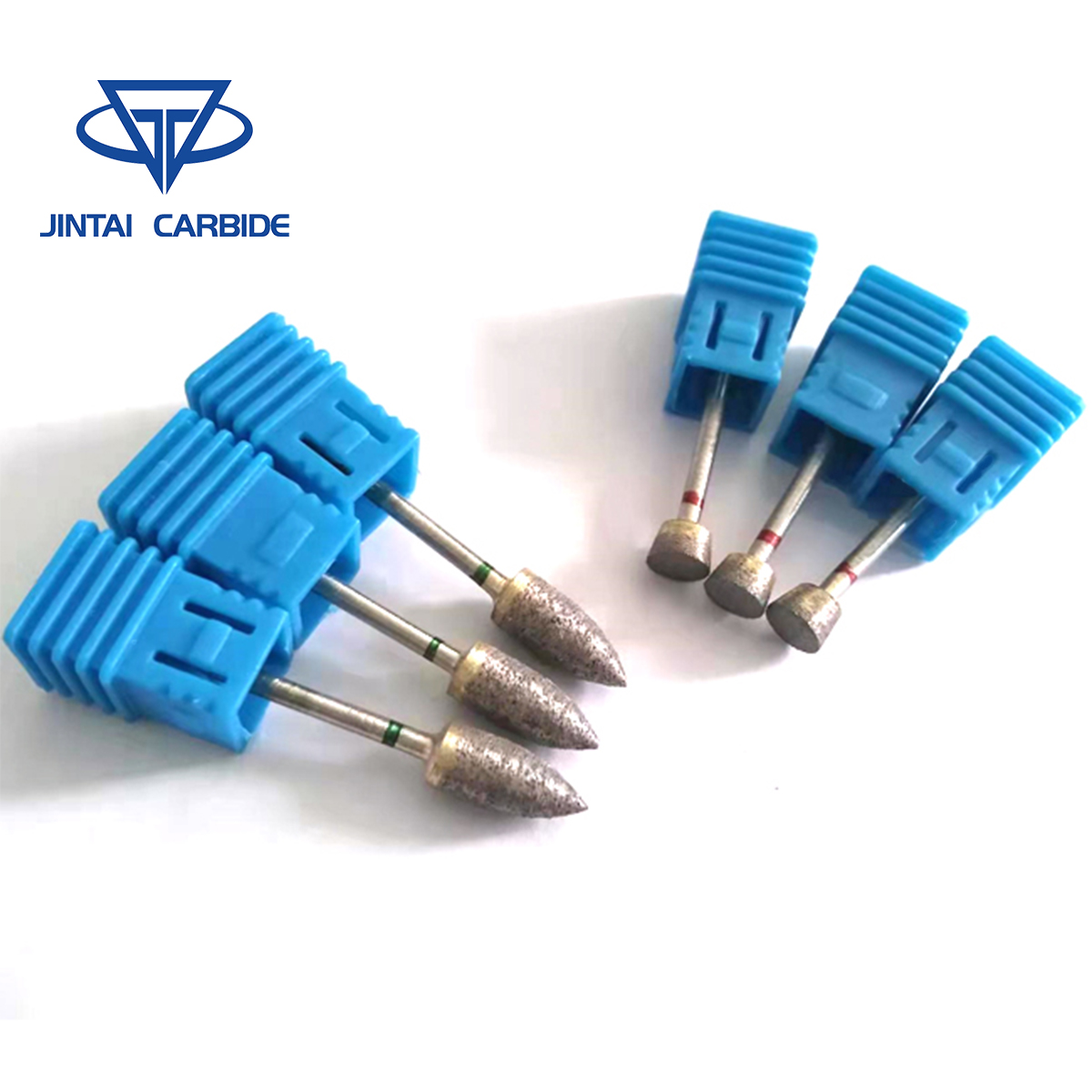

"JinTai" stamping ya mutu kuma sanyi ya mutu

Siffofin:

Zaɓi darajar da ta dace dangane da ainihin amfanin abokin ciniki da kayan da ake sarrafa su.Tare da daban-daban tungsten karfe stamping mutu maki, zai iya saduwa da bukatun daban-daban aikace-aikace, cikakken bayani dalla-dalla, madaidaicin girma girma, rage aiki girma, da kuma inganta yadda ya dace da kuma kudin-tasiri.

Ayyuka:

Yin amfani da 99.95% high-tsarki albarkatun tungsten carbide foda da cobalt, taurin sanyi ya mutu ya kai sama da HRA88, ƙarfin lanƙwasa ya wuce 2400, tare da kyakkyawan taurin ja, juriya mai girma, modules na roba, babban lanƙwasawa, da juriya mai dorewa. .

Aikace-aikace:

Dace da sanyi heading da sanyi extrusion na daidaitattun sassa Ya sanya daga jan karfe, aluminum, karfe, gami karfe kayan, kamar sukurori, rivets, da dai sauransu Common iri sun hada da lebur kai sanyi kan mutu, recessed shugaban sanyi jeri mutu, daya-jeri naushi da kuma mutu, rage sanda ya mutu, da sauransu.

Stamping Ya Mutu Ciwon Sanyi Ya Mutu

Siffofin:

Zaɓi darajar da ta dace dangane da ainihin amfanin abokin ciniki da kayan da ake sarrafa su.Tare da daban-daban tungsten karfe stamping mutu maki, zai iya saduwa da bukatun daban-daban aikace-aikace, cikakken bayani dalla-dalla, daidai m girma, rage aiki girma, da kuma inganta yadda ya dace yayin da rage farashin.

Ayyuka:

Yin amfani da 99.95% high-tsarki albarkatun tungsten carbide foda da cobalt, taurin sanyi ya mutu ya kai sama da HRA88, ƙarfin lanƙwasa ya wuce 2400, tare da kyakkyawan taurin ja, juriya mai girma, modules na roba, babban lanƙwasawa, da juriya mai dorewa. .

Aikace-aikace:

Dace da sanyi heading da sanyi extrusion na daidaitattun sassa Ya sanya daga jan karfe, aluminum, karfe, gami karfe kayan, kamar sukurori, rivets, da dai sauransu Common iri sun hada da lebur kai sanyi kan mutu, recessed shugaban sanyi jeri mutu, daya-jeri naushi da kuma mutu, rage sanda ya mutu, da sauransu.

Juriya na lalata yana da mahimmanci idan aka zo ga kiyaye ingancin saman da aiki mai dorewa.Mutuwar carbide na tungsten an tsara shi musamman don tsayayya da lalata yadda ya kamata.Waɗannan gyare-gyaren suna da juriya na musamman ga lalata kuma za su kiyaye saman ku a cikin tsaftataccen yanayi, yana tabbatar da cikakkiyar ƙare kowane lokaci.Kuna iya amincewa da gyare-gyaren mu don tsayawa gwajin lokaci kuma ku ba da kyakkyawan sakamako tare da kowane amfani.

Ko ƙira na musamman, girman musamman ko takamaiman buƙatun aiki, ƙungiyar ƙwararrun ƙwararrunmu ta sadaukar da kai don isar da gyare-gyaren da suka wuce tsammaninku.

Juriya na lalata yana da mahimmanci idan aka zo ga kiyaye ingancin saman da aiki mai dorewa.Mutuwar carbide na tungsten an tsara shi musamman don tsayayya da lalata yadda ya kamata.Waɗannan gyare-gyaren suna da juriya na musamman ga lalata kuma za su kiyaye saman ku a cikin tsaftataccen yanayi, yana tabbatar da cikakkiyar ƙare kowane lokaci.Kuna iya amincewa da gyare-gyaren mu don tsayawa gwajin lokaci kuma ku ba da kyakkyawan sakamako tare da kowane amfani.

Ko ƙira na musamman, girman musamman ko takamaiman buƙatun aiki, ƙungiyar ƙwararrun ƙwararrunmu ta sadaukar da kai don isar da gyare-gyaren da suka wuce tsammaninku.

Saki madaidaicin ƙarfin Tungsten Carbide Molds!A matsayin ƙwararren masani na e-kasuwanci na kan iyaka, kun isa madaidaicin maƙasudin tungsten Carbide Molds na saman-layi wanda ya yi fice a aikace-aikacen gyare-gyare iri-iri, yana tabbatar da daidaito da dorewa.

Ƙwararren Ƙwararren Ƙwararrun Tungsten Carbide Molds ɗinmu yana ba da ƙarfin gaske da juriya, yana mai da su zaɓi na ƙarshe don gyare-gyaren ayyuka a masana'antu kamar mota, lantarki, da ƙari.Amince da waɗannan gyare-gyaren don sadar da sakamako marasa aibi da tsawaita rayuwa, canza tsarin gyaran ku.

Bayan tsananin taurin su, Tungsten Carbide Molds ɗinmu suna nuna juriya na zafi mai ban sha'awa, yana ba da tabbacin ingantaccen aiki har ma a ƙarƙashin mafi yawan yanayin zafi mai ƙarfi.Ƙware ikon su don kula da madaidaicin siffofi da dogaro, ƙarfafa ku don haɓaka yawan aiki da rage farashin samarwa.

A JINTAI, muna alfahari sosai wajen isar da samfuran da suka wuce ingantattun ma'auni.Kowane Tungsten Carbide Mold yana fuskantar gwaji mai tsauri, yana tabbatar da daidaito da inganci, yana ba ku damar cimma sakamako mara kyau a cikin ayyukan gyaran ku.

Rungumar inganci da ingantaccen farashi tare da ƙimar Tungsten Carbide Molds ɗin mu, kuma ku sami gasa a cikin masana'antar ku.Haɗin gwiwa tare da mu a yau don sanin aikin mara misaltuwa waɗannan gyare-gyaren suna kawo wa ayyukan gyare-gyarenku.

Zaɓi JINTAI don amintacce, babban aikin Tungsten Carbide Molds, kuma ku shaida yuwuwarsu ta gaskiya wajen haɓaka kasuwancin ku zuwa sabon matsayi.Sanya odar ku a yanzu kuma ku yi amfani da ikon mafita na gyare-gyaren saman mu.

Jerin Darajoji

| Daraja | ISO Code | Kayan Aikin Jiki (≥) | Aikace-aikace | ||

| Yawan yawa g/cm3 | Hardness (HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Ya dace da mashin ɗin ƙarfe na simintin ƙarfe da ƙarfe mara ƙarfe. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥ 1420 | Ya dace da mashin ɗin daidaitaccen mashin ɗin ƙarfe da ƙarancin ƙarewa na simintin ƙarfe da ƙarfe mara ƙarfe, da kuma sarrafa ƙarfe na manganese da ƙarancin ƙarfe. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Ya dace da ƙaƙƙarfan ƙaƙƙarfan mashin ɗin ƙarfe na simintin ƙarfe da ƙarfe mai haske, kuma ana iya amfani da shi don injin ƙarfe na ƙarfe da ƙarancin ƙarfe. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥ 1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Ya dace da shigar da tasirin rotary hakowa da jujjuyawar tasirin hakowa. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Ya dace da shigar da haƙoran haƙoran haƙora masu siffar chisel ko conical don injunan hako dutse masu nauyi don magance ƙera dutsen. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Ya dace da gwajin tensile na sandunan ƙarfe da bututun ƙarfe a ƙarƙashin ƙimar matsi mai girma. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Dace da yin stamping mutu. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Ya dace da yin tambarin sanyi da matsawar sanyi ya mutu don masana'antu kamar daidaitattun sassa, bearings, kayan aiki, da sauransu. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Dace da daidaici machining da Semi-kammala bakin karfe da janar gami karfe. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Dace da Semi-kammala na bakin karfe da ƙananan gami karfe. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Ya dace da daidaitattun mashin ɗin ƙarfe na tushen ƙarfe, gami da ƙarancin zafin jiki na nickel, da ƙarfe mai ƙarfi. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Ya dace da yankan nauyi mai nauyi na karfe da simintin ƙarfe. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Ya dace da daidaitaccen mashina da ƙarancin ƙarewa na ƙarfe da simintin ƙarfe. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Ya dace da daidaitaccen mashina da ƙarancin ƙarewa na ƙarfe da simintin ƙarfe, tare da matsakaicin ƙimar abinci.YS25 an ƙera shi ne musamman don aikin niƙa akan ƙarfe da ƙarfe. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Ya dace da kayan aikin yankan nauyi, yana ba da kyakkyawan sakamako a cikin jujjuyawar simintin gyare-gyare da ƙirjin ƙarfe daban-daban. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Ya dace da shigar da raƙuman hakowa na rotary tasiri da hakowa a cikin tsarukan tsarukan dutse da in mun gwada da gaske. |

Tsarin oda

Tsarin samarwa

Marufi